A Game-Changing Invention: Wood and Steel in Electric Car Batteries

In an unexpected twist to the future of electric vehicle design, researchers in Austria have developed a hybrid battery casing made from wood and steel — and it might just give Tesla a run for its money. The project, known as Bio!Lib, was spearheaded by Dr. Florian Feist and his team at the Vehicle Safety Institute of Graz University of Technology. Their innovative creation offers a more environmentally friendly, fire-resistant, and energy-efficient alternative to conventional aluminum battery enclosures.

Why Replace Aluminum with Wood and Steel?

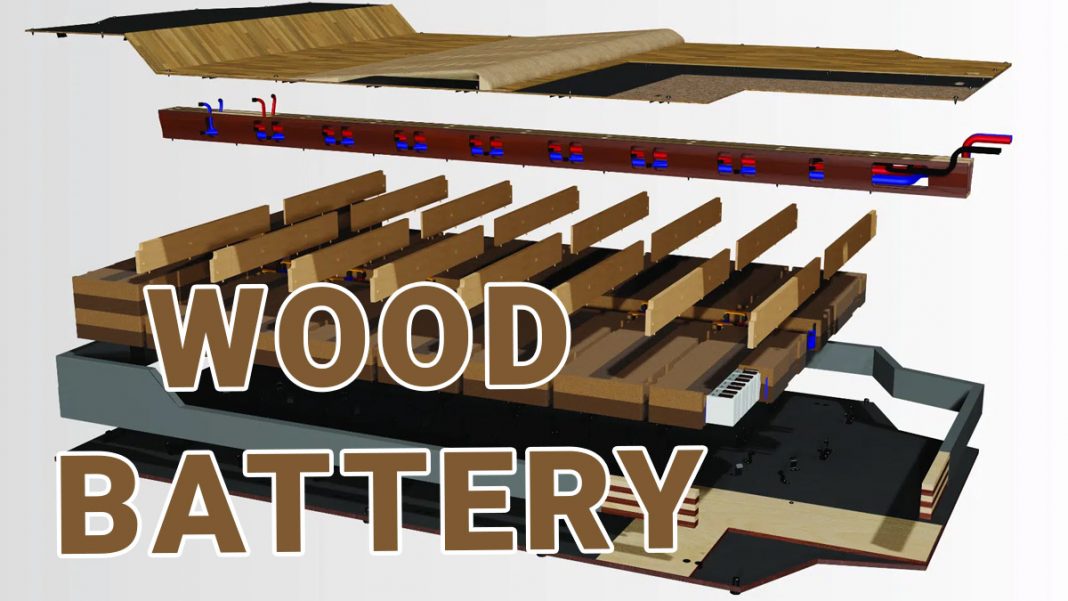

Battery enclosures play a critical role in protecting internal components from damage or fire during accidents. While most EV manufacturers, including Tesla, rely on aluminum casings, the Austrian team explored a novel combination: thin sheet steel filled with engineered wood.

Their design includes a bottom and top layer made of a steel-wood composite, reinforced with ribbed cross braces for added strength. This not only lowers the carbon footprint of production but also uses far less energy and water, helping meet growing demands for green innovation in automotive manufacturing.

Cork Wood: The Secret Ingredient in Fire Resistance

To increase heat tolerance, the researchers incorporated cork wood, known for its natural fire-retardant properties. When exposed to extreme heat, cork carbonizes instead of igniting, forming a protective layer.

During a pyrotechnic battery fire simulation, the Bio!Lib casing endured temperatures exceeding 1,300°C, retaining structural integrity and outperforming Tesla’s aluminum casing. On the opposite side of the casing, the heat transfer was around 100°C lower than in Tesla’s comparable unit — a massive improvement in safety performance.

Sustainability That Goes Beyond Performance

Following crash and fire testing, the team collaborated with the Wegener Center for Climate and Global Change to evaluate the environmental impact of the hybrid casing. Their findings showed a significantly lower ecological footprint, thanks to reductions in energy use, water consumption, and emissions during production. This adds a compelling dimension to the battery casing’s technical success.

Conclusion: A Viable Future for Natural Materials in EVs

The Austrian team’s breakthrough shows that nature-based materials can stand up to — and even outperform — traditional metals in demanding technological environments. The Bio!Lib battery casing not only delivers on performance and safety but also helps mitigate the environmental cost of EV manufacturing. While mass adoption may still be years away, this innovation sends a clear message: sustainability and safety don’t have to be mutually exclusive.